Drilling

When drilling and reconditioning an oil well a number of pipe stems are placed near the drilling mechanism and as the drilling goes deeper pipe stems are added.

At times it is necessary to extract all of the pipe for things such as examining or changing the drill bit. In this case the pipe stems are pulled out one at a time and stored in the area near the drilling mechanism. In reality, this is done quite frequently when drilling a well. Inserting and removing drill stems is a very common occurrence when drilling or servicing an oil well. There are usually different crews. One crew is in charge of drilling and the other in positioning the drill stems. It was quite common to lose count of the number of drill stems in the well.

Stokes Industries designed a device to be placed at the top of the rig that would determine the direction of the lifting cable associated with the drilling mechanism, add and subtract pipe joints as they went into or came out of the hole, while it added and subtracted the cable movement precisely. This allowed the drillers to have a very accurate indication of the number of pipe stems used and the depth of their drill bit.

Pumping

When oil production companies needed to double the capacity of two 48” diameter, 100 mile long pipelines extending from the oilfield to the refinery they decided to put in ¼ point pumping stations.

This required a pumping station to be installed at the 25 mile, 50 mile and 75 mile mark to raise the pressure in the pipeline to 900 psi. While this would double the flow of the crude oil in the pipeline the mass of this volume of oil creates a problem if there is a pump failure. It would be like shutting a door on a tunnel just as a large freight train, going 100 miles an hour, tries to enter. The collision would be disastrous. Therefore, it is common practice to install valves and pipes to bypass the pumps in case of an emergency and shut down the pumps on the entire pipeline. This needs to be done within a few milliseconds.

Stokes Industries installed a redundant monitoring and control circuit to operate over microwave communication channels between the pumping points. This system operates autonomously and notifies the pipeline operators of any problems. The system has been pumping oil for years without a problem.

Hydraulic Pump Jack

A company designing HYDRAULIC PUMPING JACK’S needed real-time information on mass and consistency of tar sands being pumped in deep wells to eliminate breakage of pumping rod.

Hydraulic pumping units, as shown above, are generally used in areas where pumping is difficult. This hydraulic unit can change its rate, stroke and force as required to capture the maximum amount of product from the well. Stokes Industries Co. LTD was asked to design a control circuit that would measure the necessary input data and control the hydraulic unit to produce maximum results.

Logging

Logging an oil well is necessary to get its best production. It requires inserting sensing devices into an oil well to measure its various geological conditions. When a Petroleum industry LOGGING COMPANY needed real-time means to compare exact replica of oil well charts to paper charts in an engineering office located thousands of miles away.

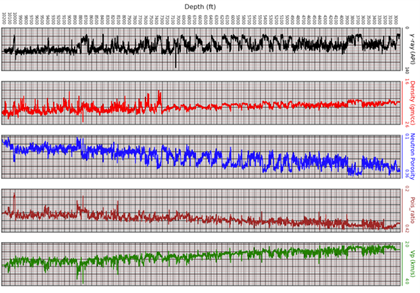

The result of this logging is a strip chart similar to that shown above. However, the chart may be 15 feet long. To determine the current condition of an oil well the oil field engineers will compare the current strip charts with those taken in the past. From this evaluation the differences in production characteristics can be mapped in the well can be altered or modified for its best production.

However, oil wells are not generally located in very clean and comfortable surroundings. In many places’ communications, except by satellite phone, is almost impossible. It is not practical to take the older charts to the field to for comparison with the current charts being generated. And because reconfiguring the well requires the same equipment used to produce the charts it is desirable to do the reconfiguration at the same time the chart is being taken.

In the past, in many locations this was not possible. Oil wells were in difficult places and petroleum engineers could be thousands of miles away. This means that the charts were recorded, then the equipment was relocated to another well while the charts were being transported to the engineering office for evaluation. Once the modifications were determined the drilling equipment was relocated and the will was serviced. This was very costly.

Stokes Industries Co. LTD developed a means to transmit the logging data directly over radio links or telephone lines and reproduce the chart in the engineer’s office exactly the same size with the correct information. This allowed very quick evaluation of charts being produced in the field and instructions given immediately for rework on the well.