Mixing and blending cosmetics can be a very dangerous operation. Many of the materials used in cosmetic production are poisonous and must be handled carefully to protect personnel and the environment. After measuring and loading these large machines they are sealed and the machine it spins on its horizontal axis as it is rotating a mixing comb on the inside. When the product is thoroughly mixed it is removed from the bottom of the machine.

PROBLEM: Because of the size and configuration of the 12’ tall blending machines loading product at the top is difficult. The products used in these machines come in 35 & 55 gallon drums and in 50 lb. to 90 lb. bags that are very heavy. Carefully measuring and mixing these products while avoiding spillage was very time-consuming.

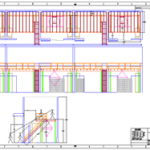

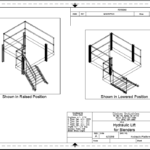

SOLUTION: Stokes Industries Co. LTD designed steel platforms which would be hydraulically rotated from the ground level to the loading level with all of the product and measuring equipment on board. Once the mixer was loaded, the platform would return to the ground, in front of the machine, to allow clearance for operation.