Overview

These systems park vehicles vertically and horizontally. They use mechanical means to move the vehicles efficiently within the parking structure. In many cases no attendant is required. This classification of mechanical parking systems is the most diverse. It contains many different types of systems that can be used in many different situations. There are systems specially designed for underground spaces and large horizontal spaces and vertical spaces. Some systems are designed for very rapid entry and exit times while other systems are designed for maximum density.

There are two broad categories of Automated Systems: Fully-Automated and Semi-Automated. The type of system selected depends on the desired usage and real estate constraints.

Getting the right system for a particular application and a specific area requires an understanding of what the different systems are capable of doing. This is why we highly recommend retaining Stokes Industries as your mechanical parking consultant so that you may receive the best advice and product recommendations for your project.

Semi-Automated Parking Systems

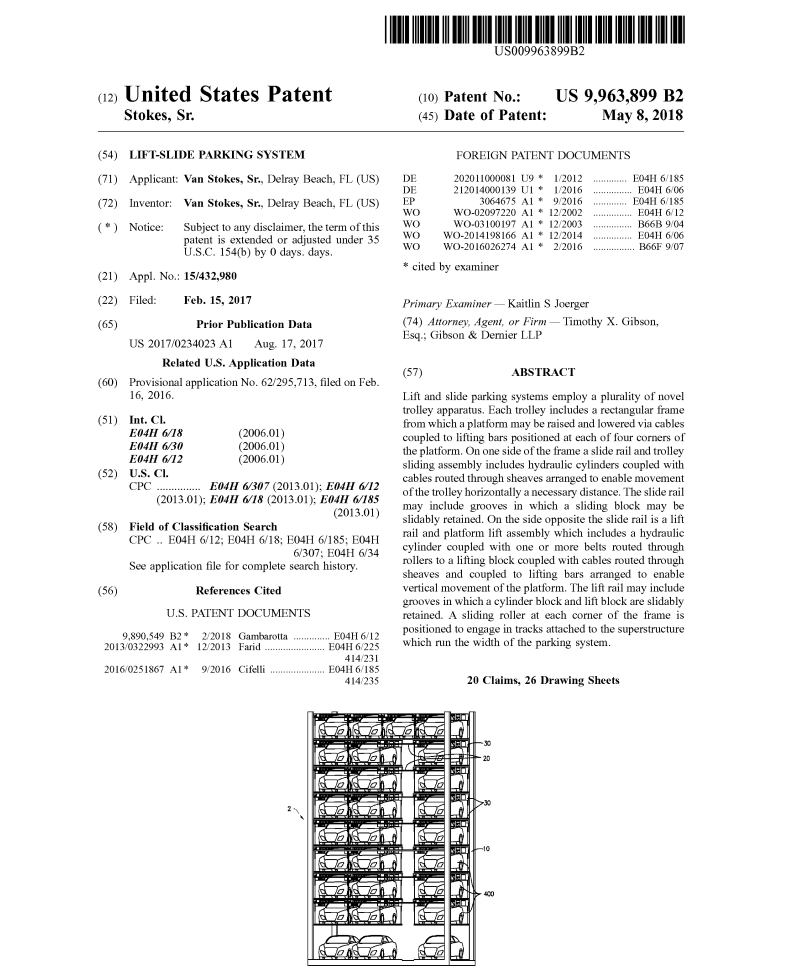

Puzzle-Park / Bi-Directional / Lift-Slide

The Puzzle-Park System, also referred to as a Lift-Slide or Bi-Directional, is probably the most popular type of Semi-Automated Parking System. It is laid out similarly to a standard parking lot configuration. Each parking space (column) requires its own entrance. It’s commonly used as a two-high indoor system. Outdoors the systems can go as much as nine-high. These units can be configured as all above ground, all below ground, or a mix of above and below ground. They can be open, partially enclosed, or fully enclosed.

This type of system has two movements. Platforms slide to the left or right to open a vertical column for the platforms above or below to be raised or lowered. Like any parking lot each space requires its own lane. Systems can be built using electric motors or hydraulics. The electric systems are much slower than the modern hydraulic systems.

Stokes Industries holds patents for these systems.

Fully-Automated Parking Systems

Tower System / Rotary System / Vertical Shuttle

The Tower System is divided into two categories: Rotary System and Vertical Shuttle.

The Rotary System works like an elongated Ferris Wheel. They are commonly used when space is at an absolute minimum.

The Vertical Shuttle System basically contain an elevator in the center, which raises and lowers a transporter. The transporter moves vehicles into and out of parking spaces at each level. These systems can be made any height – above, below, or split grade.

When systems are built into a high-rise buildings they are generally placed in the core along with the building elevators and mechanical systems. Sometimes they are built as an attachment to the building (as seen above) and sometimes they are built as stand-alone structures.

Some of the newer models, like our patented Stokes Garage, have up to eight parking spaces per level, all serviced by the same centrally located Transporter.

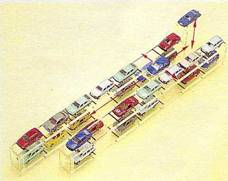

Warehouse System

This is a more modern version of the Pigeonhole System that uses transporters at each level to move the vehicles from the pickup area to the parking area along straight access routes. Modern versions of the warehouse system can operate much faster than the circulation systems but are more complicated.

There are two major classifications for this type of system; Platform Operation, sometimes called a sliding platform or pallet system and; Conveyor Operation , which uses no platform. Some versions of warehouse systems are capable of parking vehicles two or more deep on each side. This increases the concentration of vehicles but decreases the retrieval speed when the outside vehicles must be relocated to gain access to the inside vehicles. Intelligent computer programs and good control systems can greatly reduce this sorting time.

Vertical Circulation System

The Vertical Circular System is the second most concentrated way of parking vehicles. Normally used in narrow spaces where horizontal circulation system won’t fit. Operates similar to the horizontal system except the end platforms are transferred up and down to create the empty spaces. Most common installation is below ground with elevator access; however the system can be built above ground or as a combination system. This type of system is usually fabricated from structural steel. Operational speeds are moderate unless the system is very long. If part of the system is at ground level than access to the system can be made anywhere along its length and is not restricted to the elevators on the ends. Mechanical design is fairly simple and installation costs should be moderate. Speeds can be increased with proper the implementation of a computerized access systems.

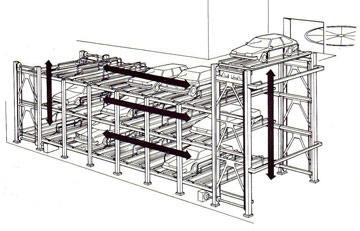

Horizontal Circulation System

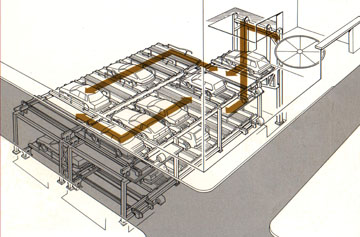

The Horizontal Circulation System is the most concentrated way to park vehicles. There is almost no wasted space and is usually used below ground with elevator access. It is possible to park one thousand (1,000) vehicles in 120,000 square feet, 7 feet in height or 840,000 cubic feet. The platforms are circulated round the floor area horizontally by moving one line in one direction and an adjacent line in the opposite direction towards an empty space. The platforms on the ends are then transferred foreword and rearward, in opposite directions, to create a new empty space on the opposite ends of the two lines. Normally used for longer-term parking as recovery speeds can be slow for long systems. Mechanical design is fairly simple and installation costs should be moderate. Operational speeds are slow but retrieval times can be increased with proper design of the arrival and departure areas. These systems are made from structural steel which generally can be disassembled and salvaged and the volume can easily be reconfigured once the structural steel has been removed.

Combination Vertical and Horizontal Circulation System

A more complex combination of the Vertical and Horizontal circulation systems which increases the operational speed by increasing the number of transfer points. Platforms are transferred up, down, foreword and rearward to create empty spaces.